The Process of Tile Making Machines: From Raw Material to Beautiful Floors

A Tile Making Machine is a set of industrial equipment used to manufacture tiles for floors, walls, and roofs. These tiles can be made from ceramic, porcelain, or even metal and are known for their strength, durability, and beautiful designs. The machine automates a process that was once done by skilled artisans, allowing for perfect consistency and intricate patterns. The journey of a tile involves several steps, and different machines are often used for each part of the process.

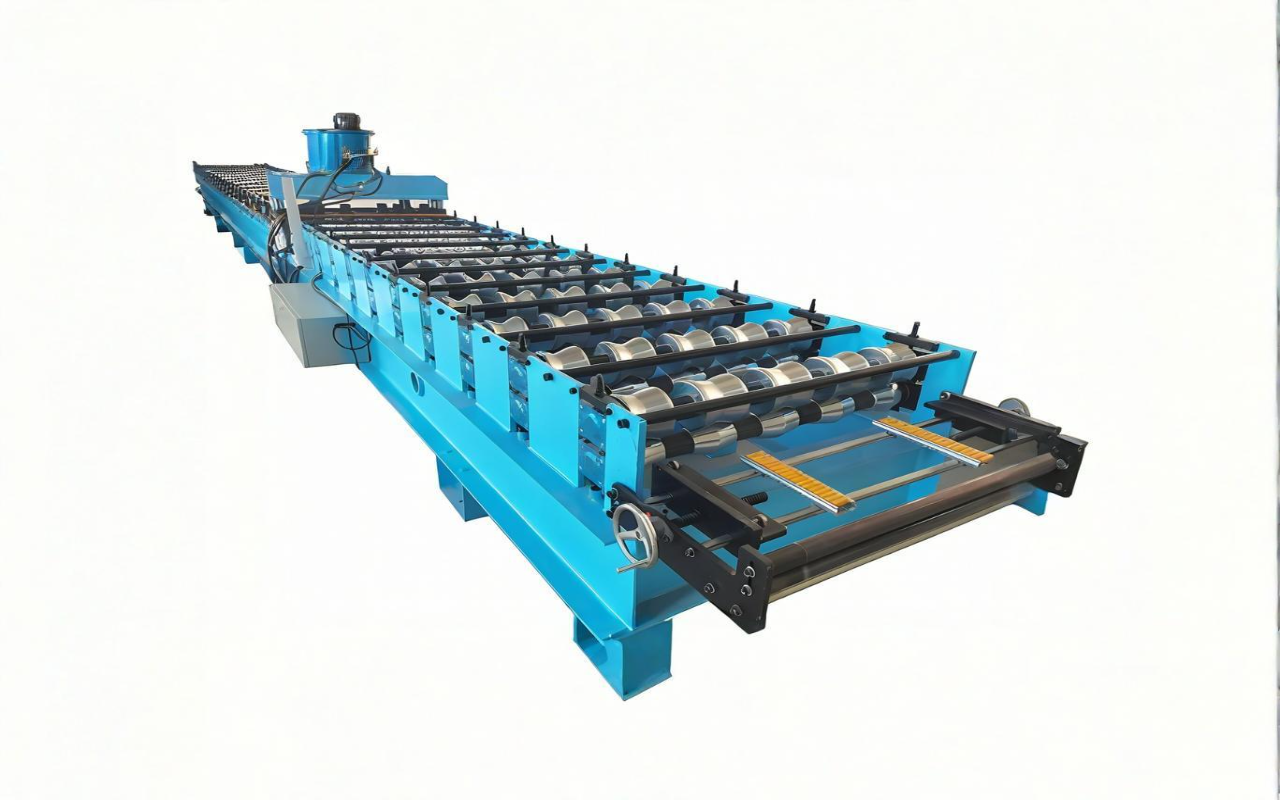

Tile making machines are not just one machine but a complete production line. Key types of equipment in this line include:

- The Press Machine: This is the heart of the process. It takes powdered clay and uses a powerful hydraulic press to compact it into the desired tile shape inside a mold. The pressure can be enormous, creating a very tough “green” (unfired) tile.

- The Glazing Line: After pressing, tiles are often coated with a liquid glass-like substance called glaze. Robots or automated sprayers and waterfalls apply the glaze, which will give the tile its color, pattern, and shiny, protective surface.

- The Kiln (Furnace): This is a massive oven where the glazed tiles are fired at extremely high temperatures. This process melts the glaze and hardens the clay, making the tile waterproof and very strong.

The primary function of tile making machinery is to produce decorative and functional coverings for buildings. The automated production ensures that every tile in a batch is exactly the same size and thickness, which is crucial for easy installation. These machines make it possible to create a huge variety of designs, textures, and colors, contributing to the beauty and style of homes, offices, and public spaces. By efficiently producing these materials, tile making machines play a vital role in the construction and interior design industries.