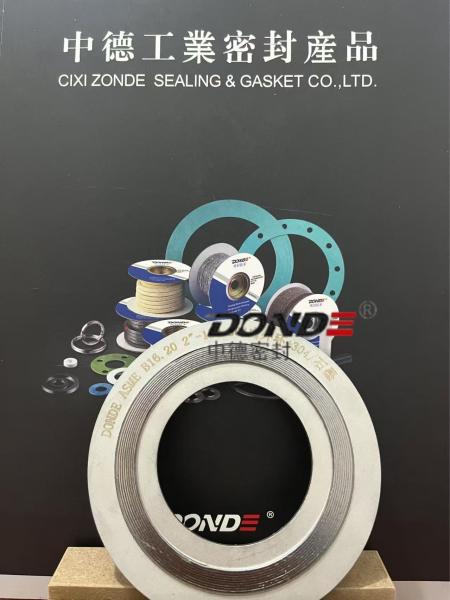

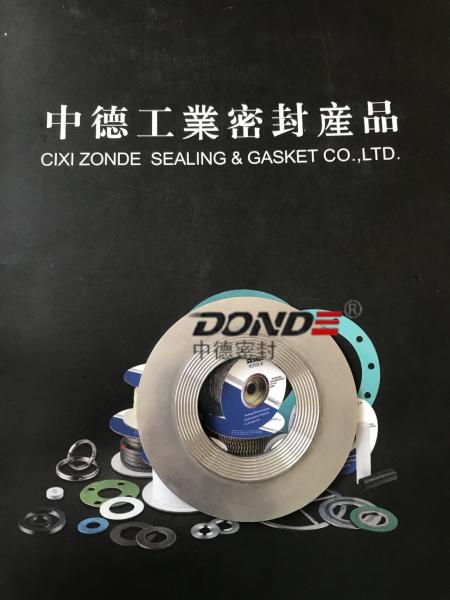

wave tooth composite gasket

gasket

Price: 10

Metal wave-tooth composite gaskets are generally processed with a precision lathe or a dedicated milling machine to form concentric wave-shaped grooves on both sides of the metal flat gasket. The tooth tips on the upper and lower surfaces are staggered to provide better compression and rebound performance. Depending on different media and working conditions, flexible graphite, PTFE, asbestos-free board or other soft metals can be adhered to both sides of the gasket. By taking advantage of the sealing property of the soft covering layer and the strength and elasticity of the metal, a better sealing effect can be achieved.

Metal wave-tooth composite gaskets are mainly used in the petroleum, chemical, metallurgical, power, shipbuilding, mechanical and other industries for sealing high-pressure and high-temperature pressure vessels, heat exchangers, condensers and pipe flange connections.