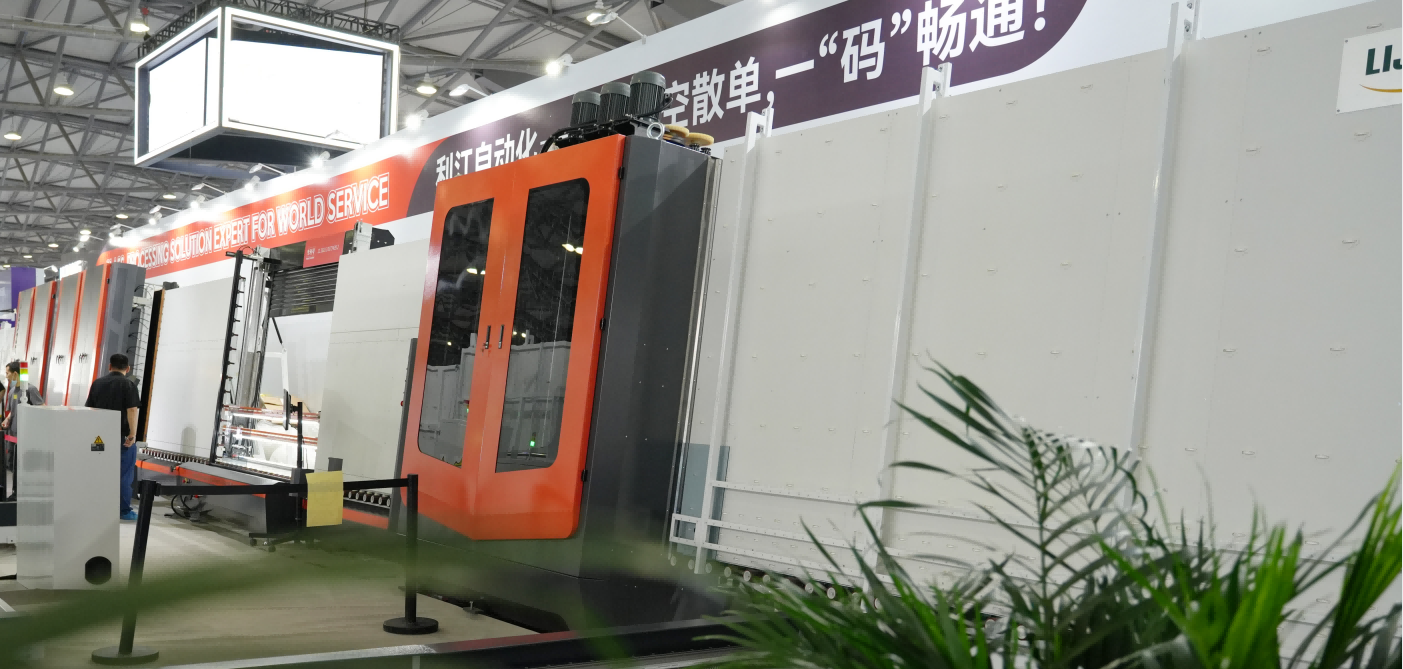

Vertical Insulating Air-floating Glass Processing Line

LJBZ2030GF/LJBZ2535GF

Vertical Insulating Air-floating Glass Processing Line can press and fill gas Two pieces of IGU in once time, high work efficiency.

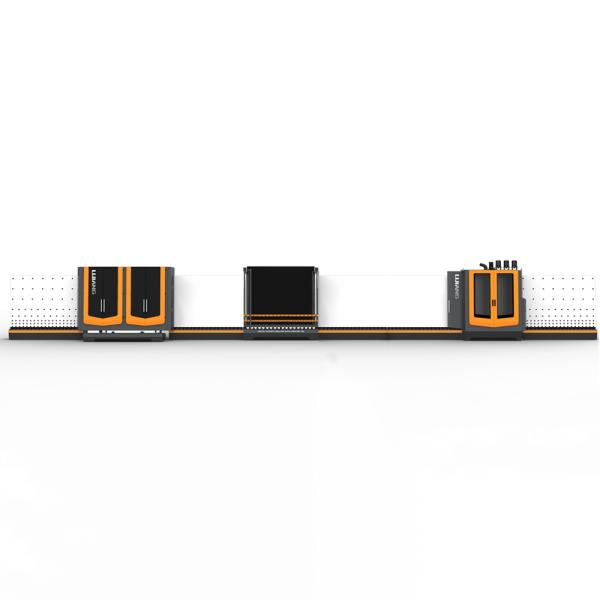

Vertical Insulating Air-floating Glass Processing Line has 7 sections:

01 transfer section

Coating detection mechanism, automatic detection of offline Low-e film

02 washing and drying section

03 discharge section

04 inspection and spacer frame installation section

05 transfer section with thickness measure

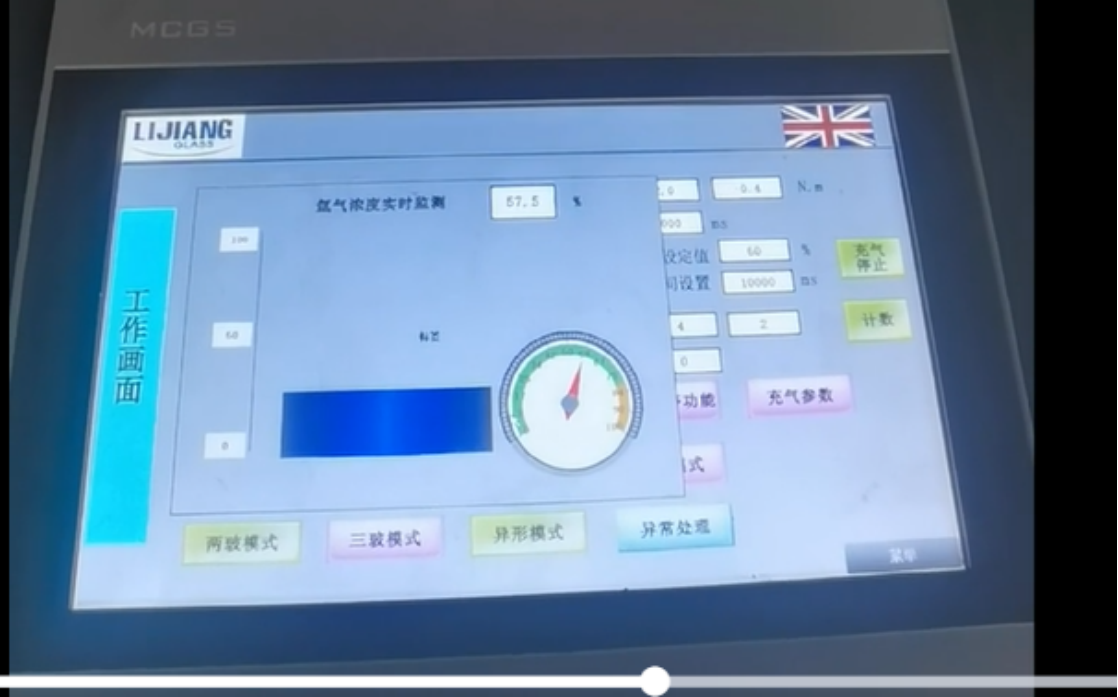

06 pressing sectionAutomatic Gas filling can set gas value and display the process of filling online with high gas concentration(Options)

07 discharge section

• Storage glass

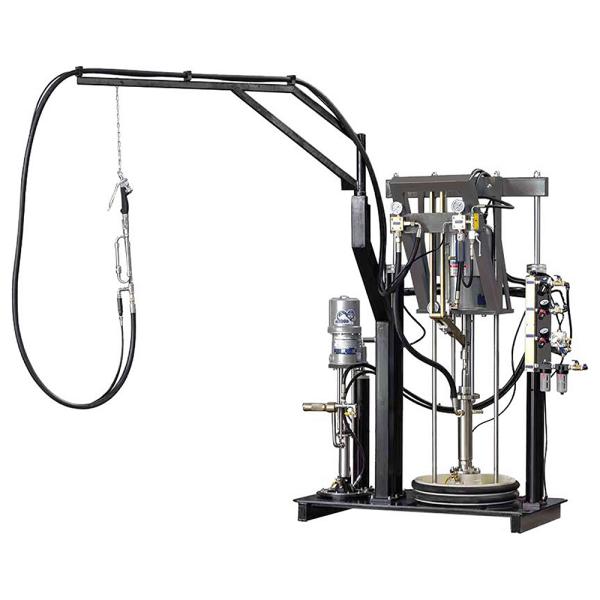

• Can be connected to any brands of sealing robot machine

| Voltage | 380V50Hz3P | |||

| Total power | KW | 41 | 44.5 | 58 |

| Washing speed | m/min | 2~10 | ||

| Maximum working speed | m/min | 45 | ||

| Minimum glass size | mm | 450*280 | ||

| Maximum glass size | mm | 2000*3000(once) | 2500*3500 | |

| 2000*3500 (Twice) | 2500*4000 (Twice) | |||

| 2500*5000(Twice Add auxiliary suction cup) | ||||

| Flat glass thickness | mm | 3-15(Option 3-30) | ||

| Washing brushes | Pieces | 6 | ||

| Maximum thickness of | mm | 60 | ||

| insulating glass | ||||

| Total gas consumption | L/min | 1200 | ||

| Conveyer roll height | mm | 520 | ||

| Dimension (L*W*H ) | mm | 20200*3500*3200 | 23800*3500*3700 | 27200*3500*3700 |