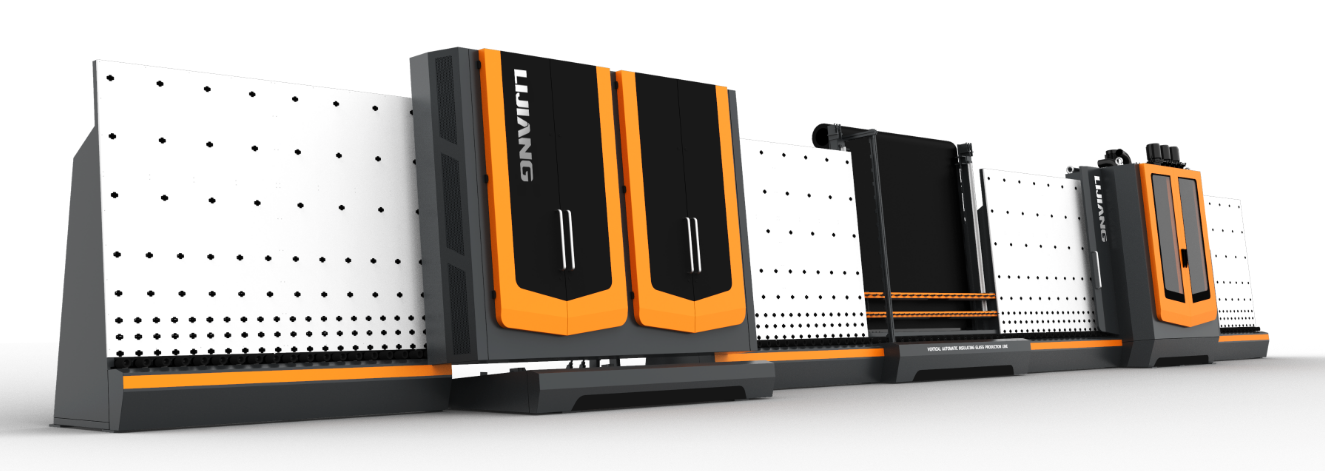

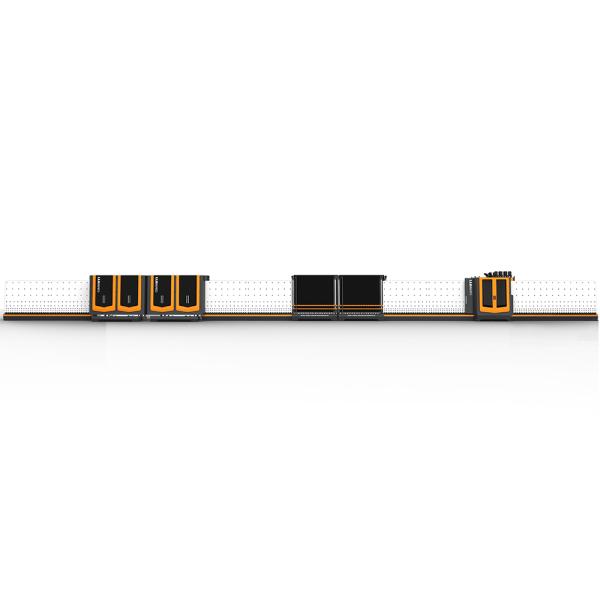

Vertical Insulating Glass Processing Line

LJBZ2030/LJBZ2535

Vertical Insulating Glass Processing Line applicable to produce triple IG and shaped IG

Insulating Glass Processing Line has 7 sections:

01 transfer section

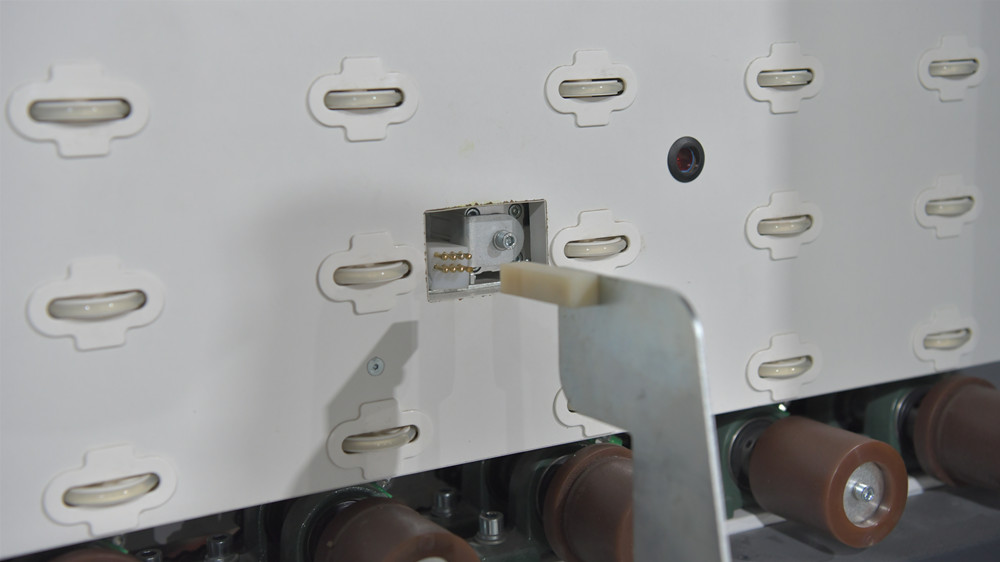

Coating detection mechanism, automatic detection of offline Low-e film

02 washing machine

03 discharge section

04 inspection and spacer frame installation section

05 transfer section with thickness measure

06 pressing section

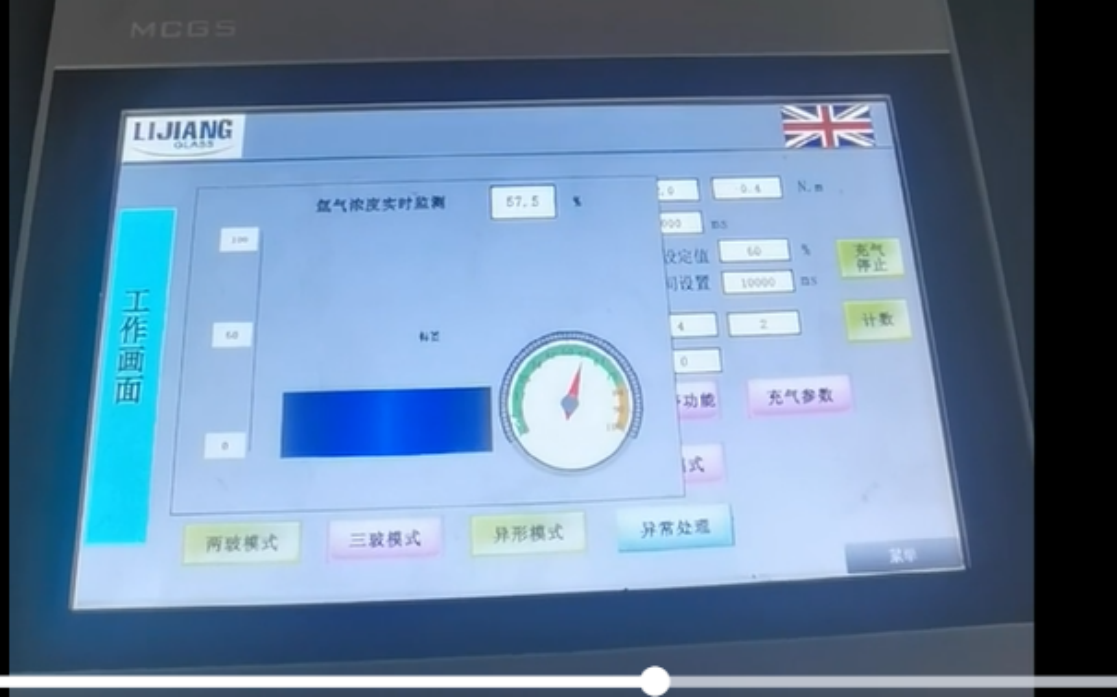

Automatic Gas filling can set gas value and display the process of filling online with high gas concentration(Options)

07 discharge section

• Storage glass

• Can be connected to any brands of sealing robot machine

| Unit | LJBZ2030 | LJBZ2030G | LJBZ2535 | LJBZ2535 | LJBZ2535 | |

| Voltage | 380V50Hz3P | |||||

| Total power | KW | 39.5 | 36 | 41 | 39.5 | 44 |

| Washing speed | m/min | 2~10 | ||||

| Maximum working speed | m/min | 45 | ||||

| Minimum glass size | mm | 450*280 | ||||

| Maximum glass size | mm | 2000*3000(once) | 2500*3500 | |||

| 2000*3500 (Twice) | 2500*4000 (Twice) | |||||

| 2500*5000(Twice Add auxiliary suction cup) | ||||||

| Flat glass thickness | mm | |||||

| Washing brushes | Pieces | 6 | ||||

| Maximum thickness of insulating glass | mm | 60 | ||||

| Total gas consumption | L/min | 1200 | ||||

| Conveyer roll height | mm | 520 | ||||

| Dimension(L*W*H ) | mm | 20200*3500*3200 | 23800*3500*3700 | 27200*3500*3700 | ||