The Different Methods of Pipe Making Machines for Industry and Plumbing

A Pipe Making Machine is industrial equipment designed for the continuous production of pipes and tubes. These pipes are essential for modern life, used for carrying water, sewage, gas, and oil, as well as in construction and industrial applications. These machines transform raw materials like steel, plastic (PVC, HDPE), and concrete into long, hollow cylinders of a specific diameter and thickness. The method used depends entirely on the material and the intended use of the pipe.

There are several main categories of pipe making machines, each using a different technology:

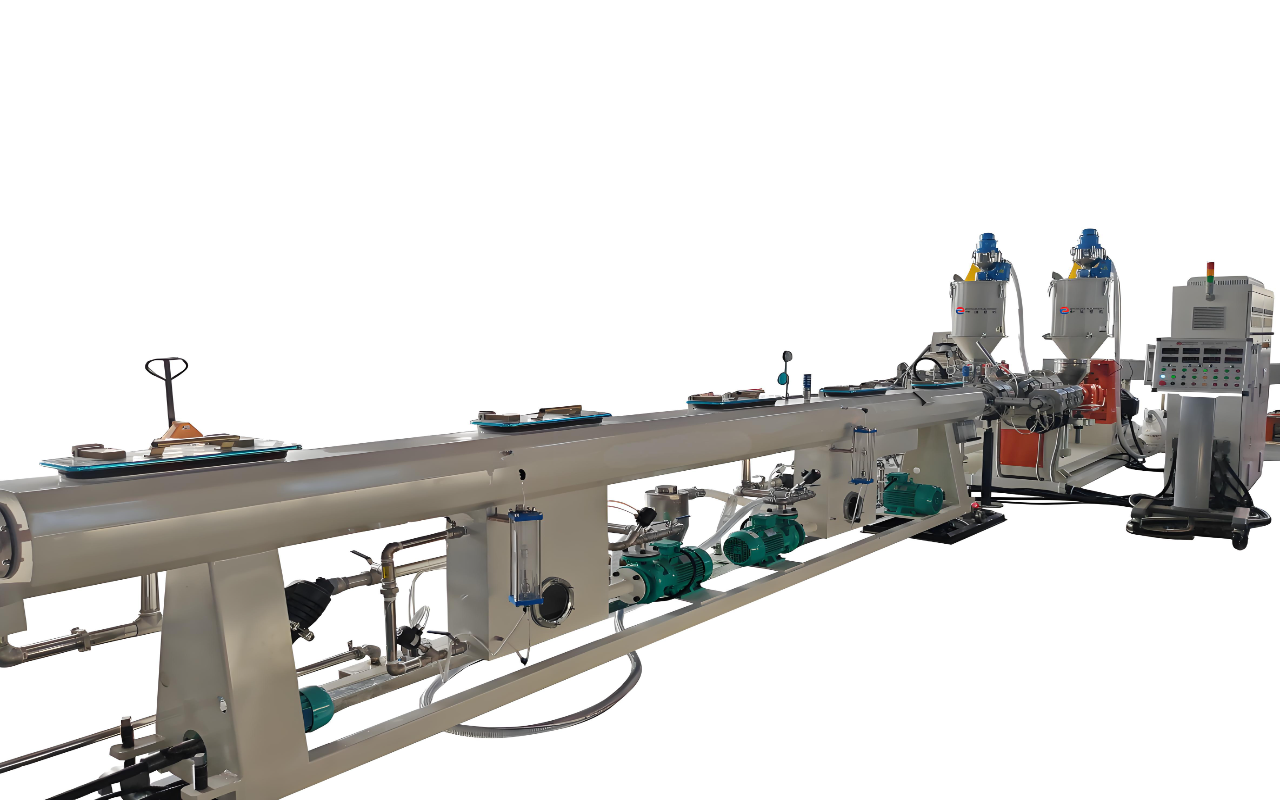

- Extrusion Machines: This is the primary method for making plastic pipes. The machine heats plastic granules until they melt. The molten plastic is then forced through a die (a shaped hole), which forms it into a pipe shape. As it comes out, it is cooled and cut to length.

- Spiral Welding Machines: For large-diameter metal pipes, a steel strip is coiled into a spiral shape. The edges of the strip are then welded together to form a strong, continuous seam along the length of the pipe.

- Centrifugal Casting Machines: This is often used for concrete or ductile iron pipes. The mold is spun at a high speed. The centrifugal force pushes the liquid material against the walls of the mold, forming a pipe that is very strong and consistent in thickness.

The function of pipe making machines is fundamental to infrastructure. They create the vital “veins and arteries” of a city. Without them, we would not have reliable systems for clean water delivery, wastewater removal, or natural gas distribution. They also produce pipes used in construction for scaffolding and in industry for transporting chemicals and other materials. The ability to mass-produce durable, reliable, and affordable pipes in various sizes makes these machines indispensable for public health, sanitation, and industrial development.