Woodworking Machinery Parts: Critical Components Ensuring Efficiency and Durability

What are Woodworking Machinery Parts?

Woodworking machinery parts include components like blades, bearings, motors, and belts that keep equipment operational. These parts are vital for maintaining performance, safety, and longevity in saws, planers, routers, and other woodworking machines.

Categories of Machinery Parts

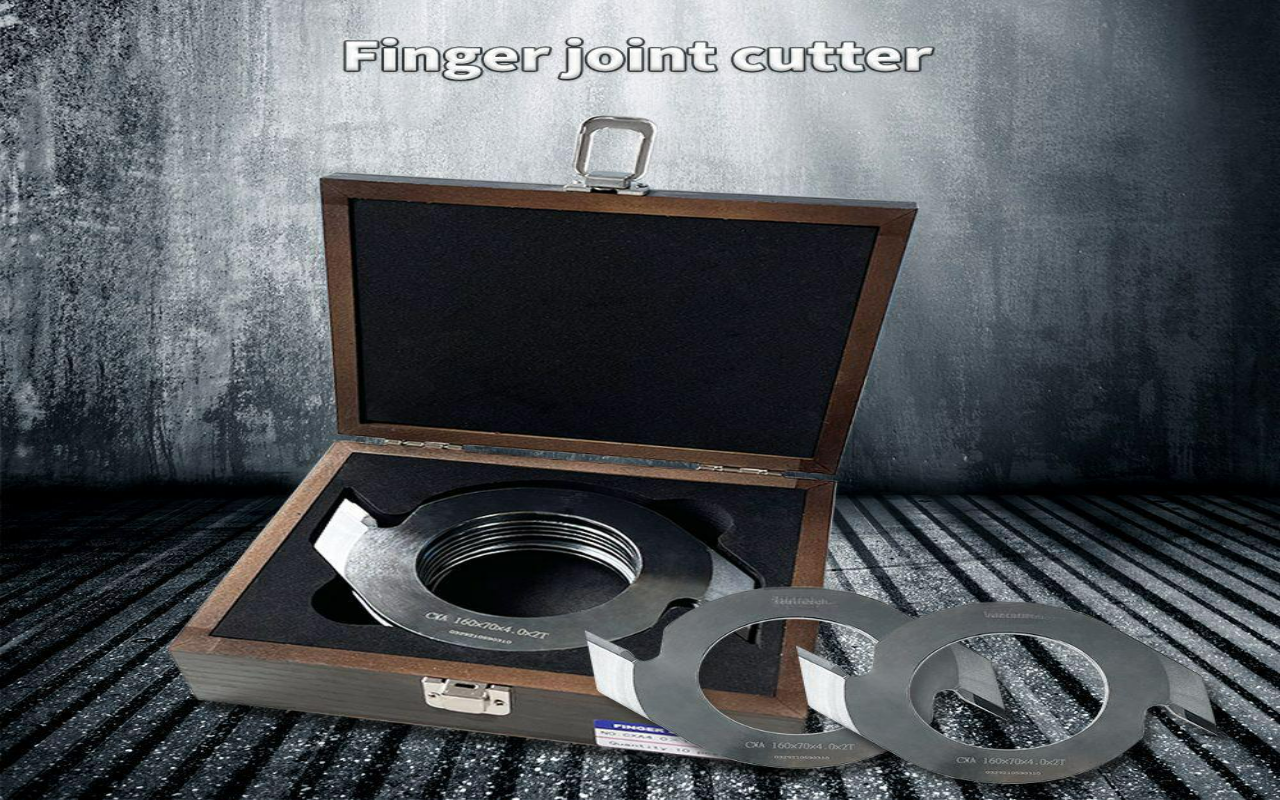

- Cutting Components

- Saw blades, router bits, and planer knives.

- Power Transmission Parts

- Belts, gears, and pulleys for motor-driven machines.

- Guide and Alignment Systems

- Fences, rails, and laser guides for precision.

- Electrical Components

- Motors, switches, and control panels.

Key Benefits

✔ Enhanced Performance: High-quality blades ensure clean cuts.

✔ Reduced Downtime: Durable bearings and belts minimize breakdowns.

✔ Safety Compliance: Replace worn parts to prevent accidents.

✔ Cost Savings: Extend machinery lifespan with regular part replacement.

Applications

- Sawmills: Band saw blades, log carriage wheels.

- Furniture Factories: Router collets, spindle bearings.

- DIY Workshops: Replacement belts for table saws.

Maintenance Tips

- Blade Sharpening: Use diamond sharpeners for carbide-tipped blades.

- Bearing Lubrication: Apply high-temperature grease every 500 hours.

- Belt Inspection: Check for cracks or stretching monthly.

Innovations

- Carbide-Tipped Blades: Last 5x longer than steel blades.

- Smart Sensors: Monitor part wear and send maintenance alerts.