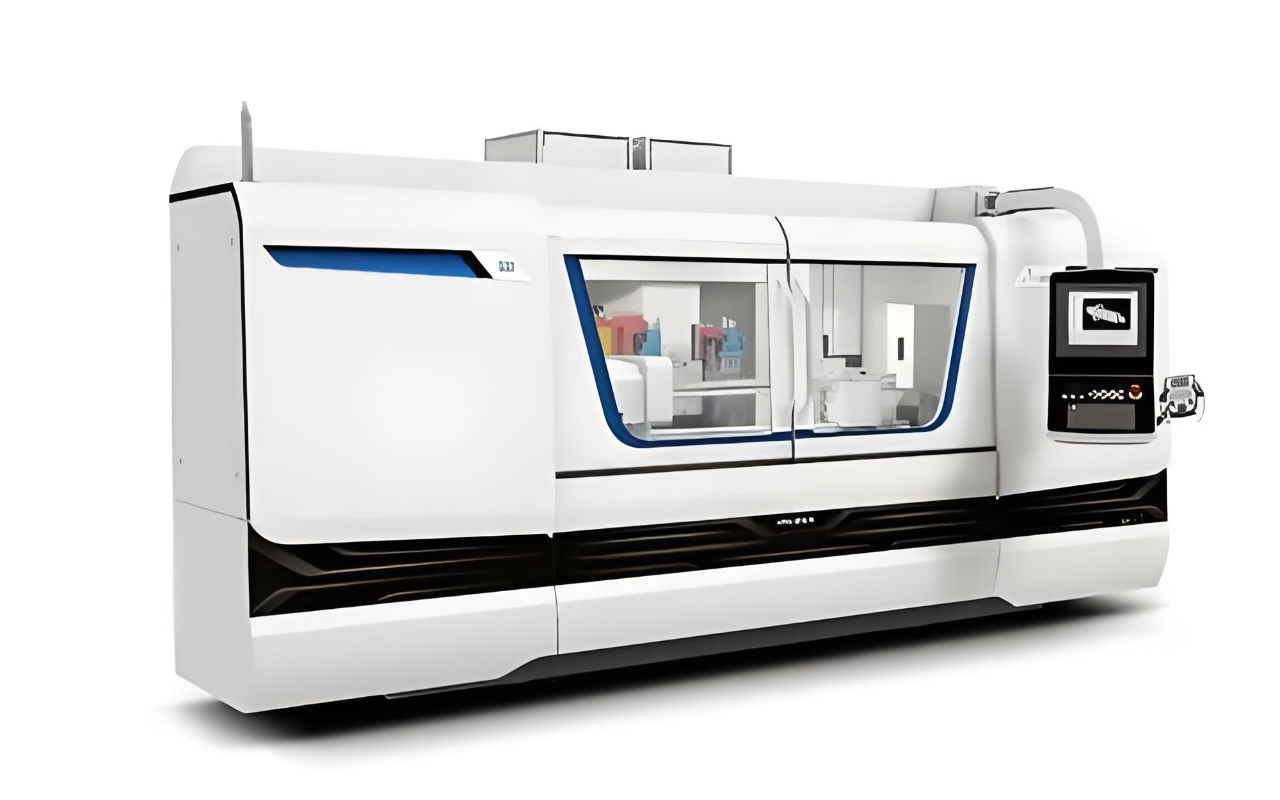

Studer Grinding Machine: Swiss Precision for Ultrafine Surface Finishing and Geometric Accuracy

What is a Studer Grinding Machine?

A Studer Grinding Machine is a high-precision CNC grinding system designed for cylindrical, surface, and universal grinding applications. Manufactured by Fritz Studer AG (Switzerland), these machines are renowned for sub-micron accuracy (±0.0001 mm) and exceptional rigidity, making them ideal for aerospace, medical, and tooling industries.

Types of Studer Grinders

- Cylindrical Grinders (e.g., S41, S33)

- External/internal grinding with hydrostatic guides for vibration-free operation.

- Universal Grinders (e.g., FavoritCNC)

- Combines OD/ID grinding, tapering, and thread grinding.

- Centerless Grinders (e.g., KC33)

- For high-volume precision pins and shafts.

Key Advantages

- Nanometer Precision: Achieves Ra 0.02 μm surface finishes.

- Thermal Stability: Granitan® polymer-concrete bases minimize thermal drift.

- Modular Tooling: Quick-change wheelheads and probes reduce setup by 70%.

- AI-Driven Optimization: Learns grinding patterns to predict wheel wear.

Applications

- Medical: Hip joint stems, surgical needle tips.

- Automotive: Fuel injector plungers, transmission shafts.

- Aerospace: Turbine blade roots, landing gear pins.

Operation Workflow

- Workholding: Mount workpiece between centers or in chucks.

- Wheel Selection: Diamond/CBN wheels for carbide; ceramic-bonded for steel.

- CNC Programming:

- Roughing: 0.02 mm depth of cut at 30 m/s.

- Finishing: 0.002 mm passes at 45 m/s.

- In-Process Metrology: Integrated probes measure dimensions every 5 cycles.

- Coolant Filtration: 5-micron filters maintain fluid purity.