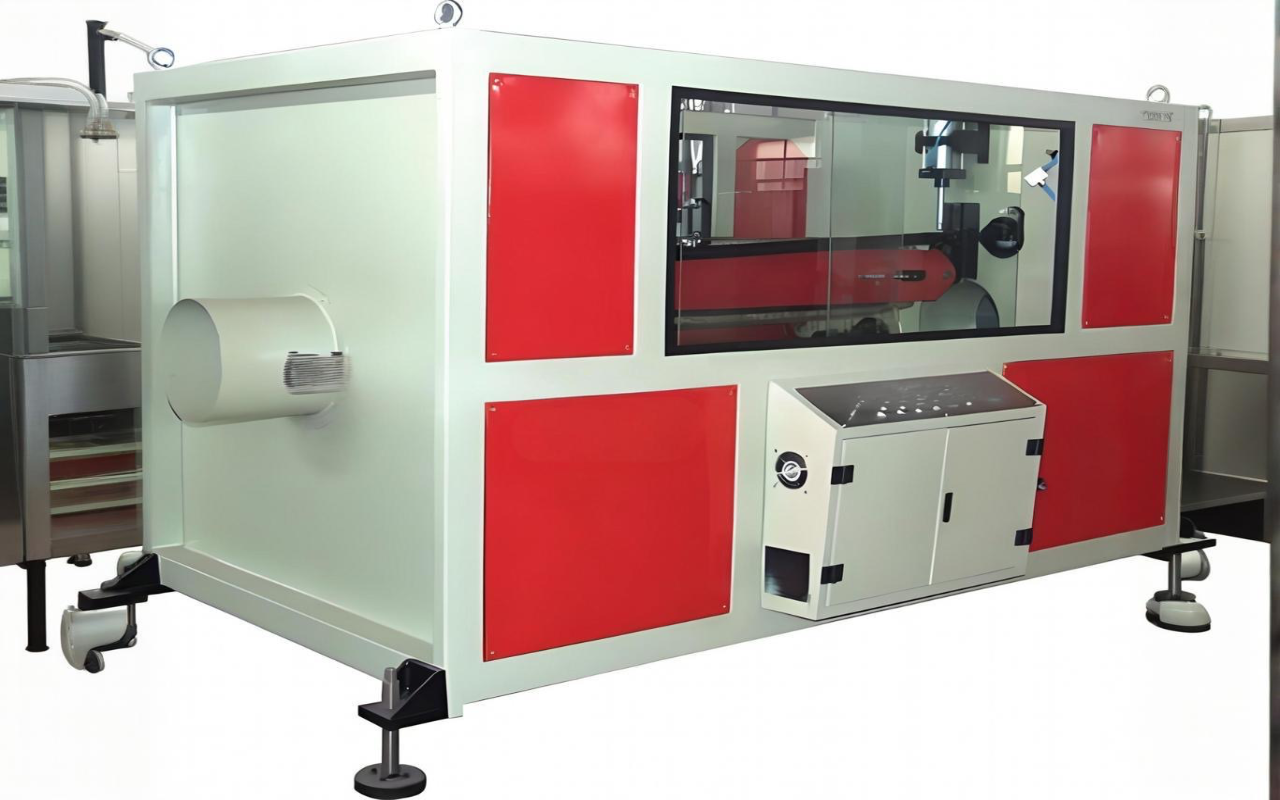

Plastic Haul-Off Machine: Ensuring Stable Tension and Speed Control in Extrusion Lines

Plastic haul-off machines (pullers) grip and pull extruded profiles, pipes, or cables at a controlled speed, ensuring consistent product dimensions and alignment in continuous production lines.

What is a Plastic Haul-Off Machine?

It uses belts, caterpillar tracks, or rollers to apply tension to extruded products, synchronizing with the extruder’s output speed to prevent warping or stretching.

Types of Haul-Off Systems

- Caterpillar Haul-Offs:

- Grip heavy profiles (e.g., PVC pipes) with rubber tracks.

- Belt Pullers:

- For delicate products like medical tubing or optical fibers.

- Roller Haul-Offs:

- Adjustable rollers for flat sheets or films.

- Capstan Pullers:

- Wrap cables around a rotating drum for high-tension applications.

Core Advantages

- Dimensional Accuracy: Maintain uniform wall thickness and diameter.

- Speed Synchronization: Match extruder output (0.1–50 m/min).

- Versatility: Handle rigid PVC, soft TPE, or reinforced hoses.

Applications

- Pipe Extrusion: Pull HDPE gas pipes at 10–20 m/min.

- Wire & Cable: Control tension during insulation coating.

- Profile Extrusion: Aluminium-plastic window frames.

Operation Guidelines

- Speed Calibration: Set puller speed to 1–5% faster than extruder output.

- Grip Adjustment: Modify track pressure based on product hardness.

- Lubrication: Apply silicone spray to caterpillar tracks weekly.

- Alignment Check: Ensure puller is centered with the extruder die.

Technological Advances

- Servo Motor Control: Auto-adjust speed via extruder torque feedback.

- Non-Slip Surfaces: Laser-etched tracks for slippery materials like PTFE.