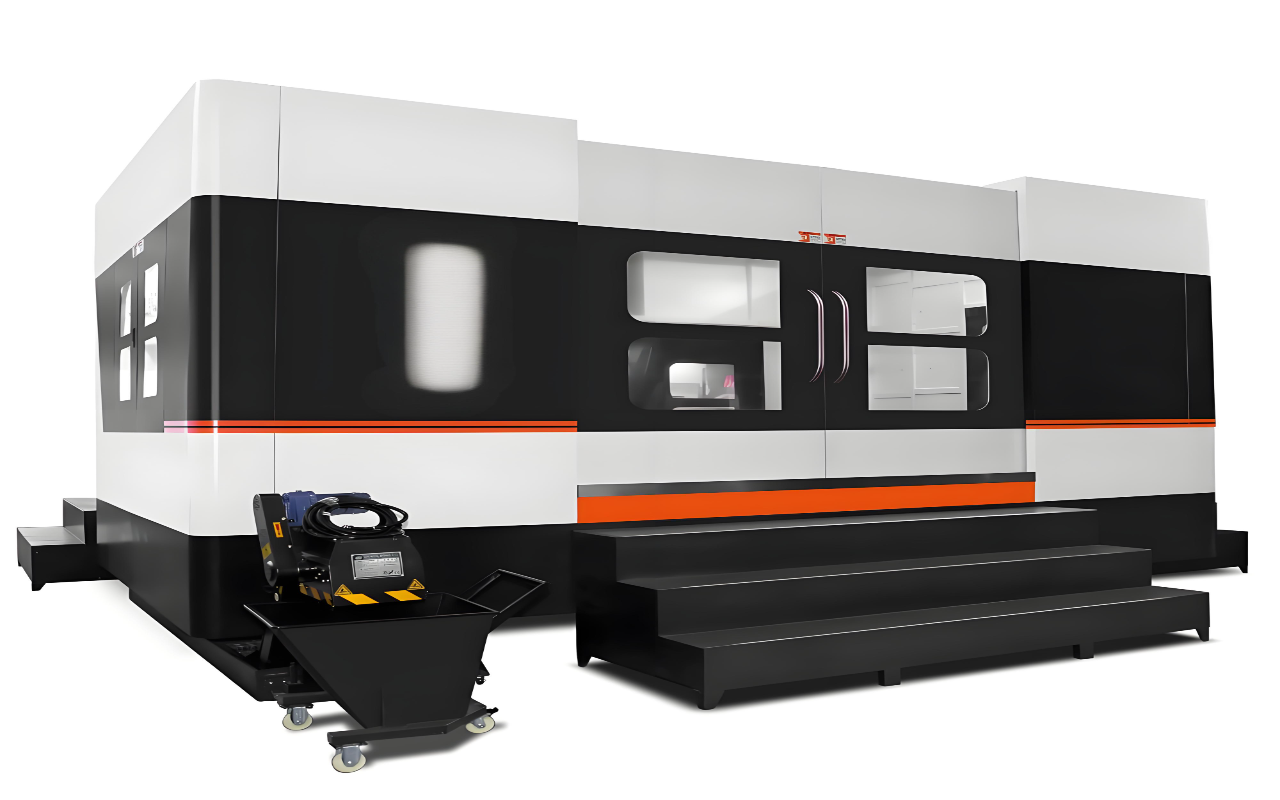

Horizontal Milling Machine: Heavy-Duty Material Removal for Industrial-Scale Production

What is a Horizontal Milling Machine?

A Horizontal Milling Machine (HMC) features a horizontally oriented spindle parallel to the worktable, using cylindrical cutters for high-efficiency material removal. Designed for robustness, it excels in slotting, grooving, and heavy stock removal on large workpieces.

Types & Configurations

| Type | Key Features | Max Workpiece |

|---|---|---|

| Bed Mill | Fixed table, moving spindle | 2,000 kg |

| Twin-Pallet HMC | Automated pallet changer | Ø1,200 × 800 mm |

| Twin-Spindle HMC | Dual spindles for simultaneous work | Ø800 × 600 mm |

| Floor-Type HMC | For extra-large parts (e.g., dies) | 10,000 kg |

Key Advantages

- Superior Chip Evacuation: Gravity clears chips efficiently, reducing downtime.

- High Rigidity: Handles 1,500 N·m cutting torque for aggressive milling.

- Tool Capacity: 40–300 tools for uninterrupted production.

- MRR Efficiency: Removes 800 cm³/min in cast iron.

Applications

- Automotive: Engine blocks, transmission housings.

- Energy: Turbine casings, valve bodies.

- Railway: Bogie frames, couplers.

Operation Workflow

- Workholding: Bolt workpiece to modular fixtures.

- Tool Selection:

- Roughing: Indexable shell mills (Ø125–250 mm).

- Finishing: Carbide end mills.

- Milling Process:

- Face milling at 0.5–8 mm depth of cut.

- Side milling for slots/keyways.

- Coolant System: High-pressure flood cooling (70 bar) for tool life.