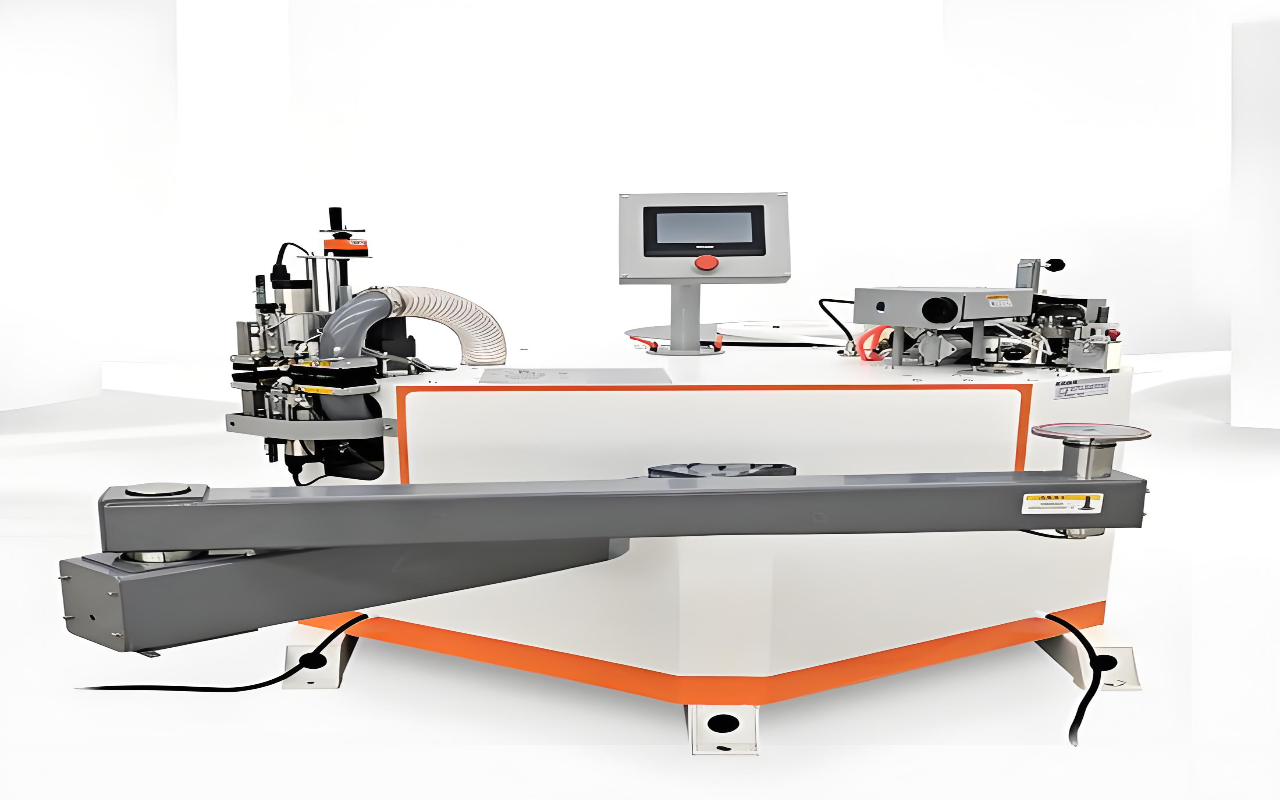

Wood Edge Banding Machine: Professional Finishing for Seamless Furniture and Panel Edges

What is a Wood Edge Banding Machine?

A wood edge banding machine is a specialized piece of equipment used to apply veneer, PVC, or ABS strips to the exposed edges of plywood, MDF, or particleboard panels. This process enhances durability, aesthetics, and moisture resistance in furniture and cabinetry.

Types of Wood Edge Banding Machines

- Manual Edge Banders

- Operated by hand for small workshops; ideal for custom projects.

- Automatic Edge Banders

- High-speed machines (10–30 meters/minute) for mass production.

- Hot-Melt Edge Banders

- Use thermoplastic adhesives for instant bonding.

- Laser Edge Banders

- Precision laser trimming for flawless edge finishing.

Key Functions and Advantages

✔ Aesthetic Enhancement – Hides raw edges with color-matched materials.

✔ Moisture Protection – Seals edges to prevent swelling.

✔ Efficiency – Processes up to 500 panels/day in automated systems.

✔ Versatility – Works with wood veneer, PVC, acrylic, and metal edges.

Applications

- Furniture Manufacturing: Table tops, cabinets, and shelves.

- Interior Design: Wall panels and decorative surfaces.

- Retail Fixtures: Display counters and shop fittings.

Operation Steps

- Material Loading: Feed panels and edge tape into the machine.

- Adhesive Application: Apply hot-melt glue or pre-coated adhesive.

- Pressure Bonding: Rollers press the tape onto the edge.

- Trimming & Buffing: Cut excess material and polish edges.

Innovations

- Vision Systems: Automatically detect panel dimensions for precise alignment.

- Eco-Friendly Adhesives: Low-VOC options for sustainable production.