Wood Boring Machine: Precision Hole Drilling for Joinery, Assembly, and Custom Woodwork

What is a Wood Boring Machine?

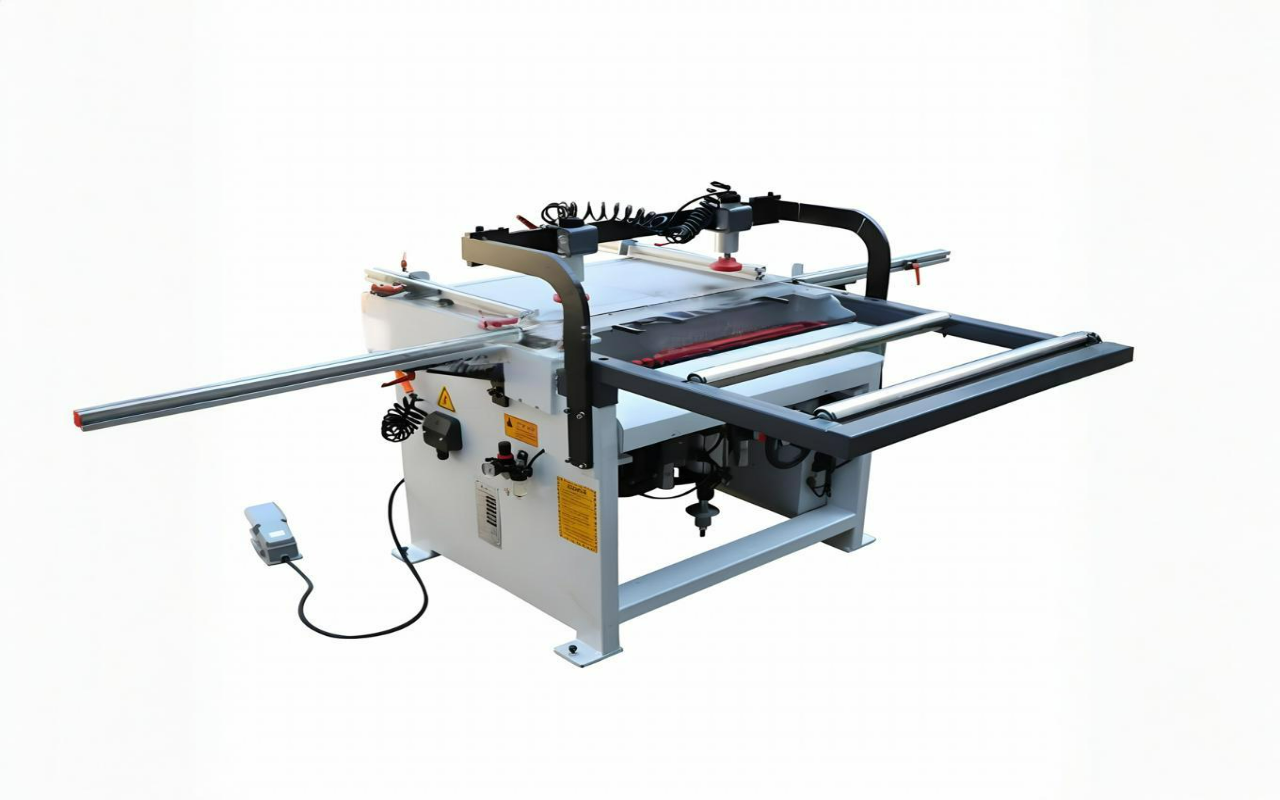

A wood boring machine is specialized equipment designed to drill accurate holes in wood for dowels, hardware installation, or artistic designs. Unlike standard drills, it offers adjustable depth, angle, and spacing control for complex woodworking projects.

Types of Wood Boring Machines

- Horizontal Boring Machines

- Drills parallel holes for shelf pins or cabinet assembly.

- Multi-Spindle Boring Units

- Simultaneously drills 2–20 holes (e.g., for chair legs or door handles).

- CNC Boring Centers

- Automated 3-axis systems for intricate patterns (e.g., musical instruments).

- Portable Boring Jigs

- Handheld guides for on-site timber framing.

Key Functions and Advantages

- Precision: Laser alignment ensures ±0.1mm hole accuracy.

- Efficiency: Drills 100+ holes/hour vs. 10–20 manually.

- Versatility: Adjustable for angles (0–45°) and depths (10–300mm).

- Strength Optimization: Reinforces joints with perfectly aligned dowels.

Applications

- Furniture Manufacturing: Cabinet carcass assembly, bed frames.

- Timber Construction: Peg-and-hole joinery in log cabins.

- Decking/Railing: Baluster hole patterns.

Operation Process

- Setup: Secure wood with vacuum clamps.

- Template Alignment: Use jigs for batch processing.

- Drilling: Engage spindles at 1,500–3,000 RPM.

- Deburring: Auto-brush attachments clean hole edges.

Maintenance & Safety

- Lubricate spindle bearings weekly.

- Replace carbide bits after 500 operating hours.