Blister Machine: Precision Packaging Solutions for Pharma, Electronics, and Consumer Goods

Blister machines automate the production of thermoformed plastic cavities (blisters) sealed with foil or film, ensuring product protection and tamper-evident packaging. These systems are vital in industries requiring sterile, high-visibility, and unit-dose packaging.

What is a Blister Machine?

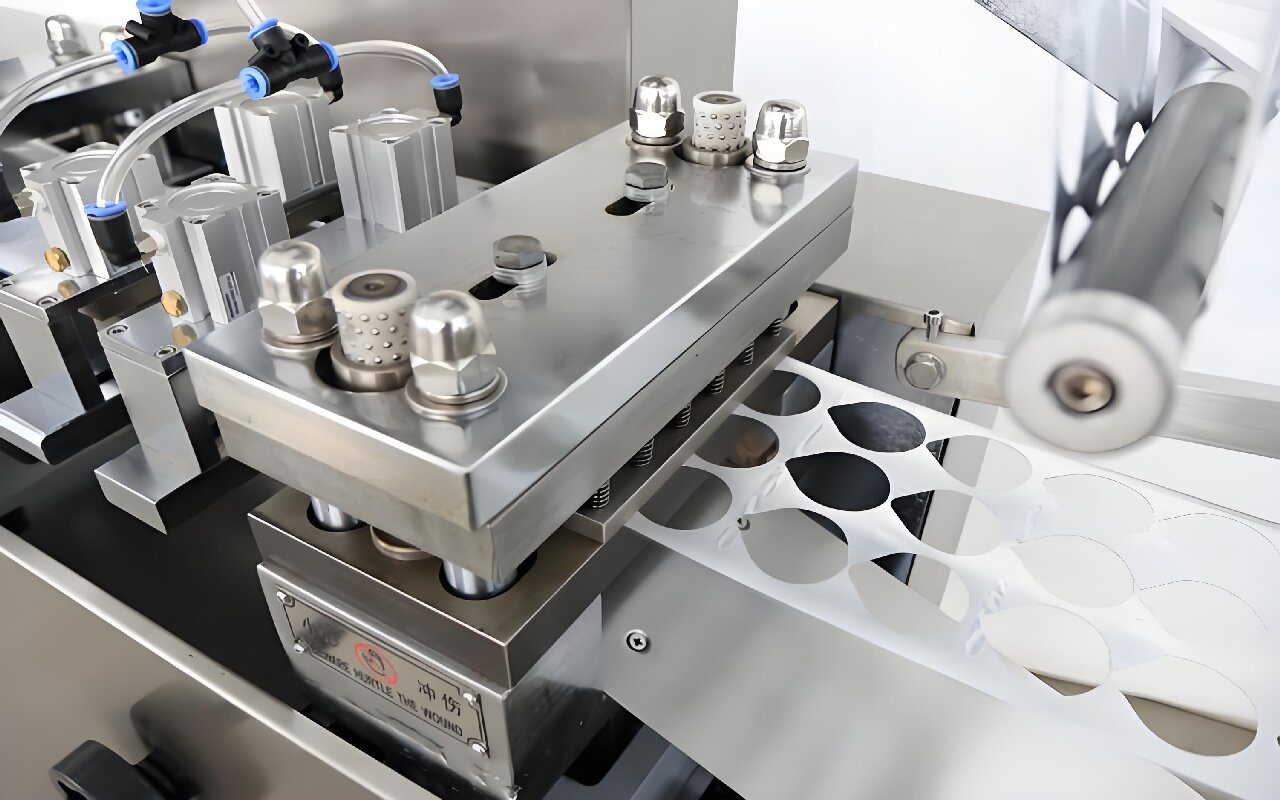

A blister machine combines thermoforming, filling, and sealing processes to create individual compartments for pills, electronics, or small parts. Key components include heating stations, forming molds, and sealing rollers.

Types of Blister Machines

- Thermoforming Blister Machines:

- Heat PVC or PET sheets to form cavities.

- Used for medical devices and consumer goods.

- Cold Forming Blister Machines:

- Shape aluminum-based laminates without heat for oxygen-sensitive drugs (e.g., nitroglycerin).

- Rotary Blister Lines:

- High-speed systems producing 600+ blisters/minute for bulk pharmaceuticals.

- In-Line Systems:

- Integrated with filling and capping for OTC medications.

Key Advantages

- Tamper Evidence: Secure seals prevent contamination.

- Customization: Adjust cavity size/shape via interchangeable molds.

- Cost Efficiency: Reduce material waste by 20% compared to manual packaging.

Applications

- Pharmaceuticals: Unit-dose pills, vaccine vials.

- Electronics: Anti-static blisters for microchips.

- Retail: Clamshell packaging for toys or batteries.

Operation Process

- Sheet Feeding: Load plastic rolls or pre-cut sheets.

- Heating & Forming: Heat to 150–200°C, mold cavities using vacuum/pressure.

- Product Loading: Auto-fill pills or components.

- Sealing: Apply lidding material (aluminum/PET) with heat and pressure.

- Cutting & Discharge: Die-cut blisters and eject finished packs.

Innovations

- NFC-Enabled Blisters: Track patient adherence via embedded sensors.

- Recyclable Materials: Use mono-material PP sheets for easier recycling.