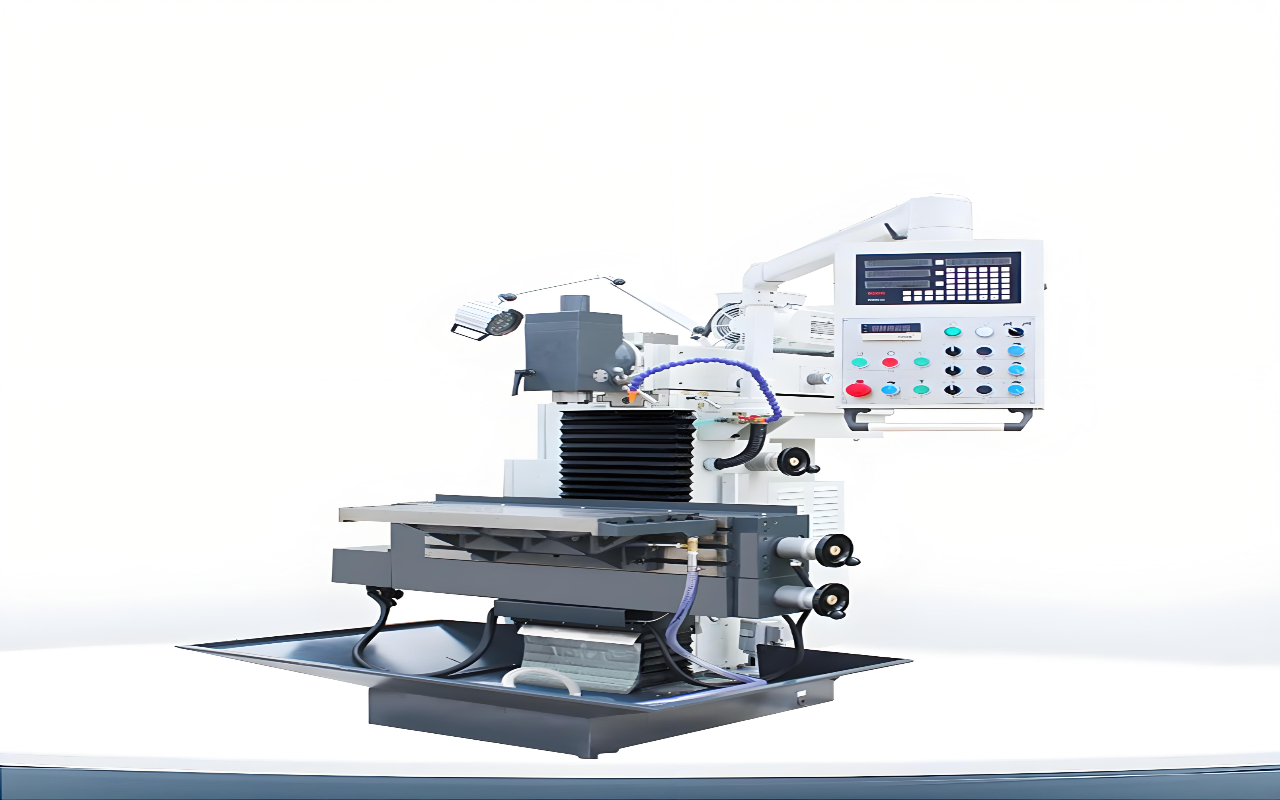

Horizontal Milling Machine: Heavy-Duty Material Removal for High-Volume Production

What is a Horizontal Milling Machine?

A Horizontal Milling Machine uses a horizontally oriented spindle to mount cutting tools, removing material via peripheral milling. Its robust design excels in slotting, facing, and heavy stock removal for large workpieces.

Categories & Capabilities

- Universal Horizontal Mills

- Swiveling table for angular cuts (±45°).

- Bed Mills

- Fixed table with moving spindle (rigidity for die/mold work).

- Pallet-Changing HMCs

- Automated pallet systems for 24/7 production.

- Twin-Spindle Mills

- Double output for symmetric parts (e.g., axle housings).

Key Advantages

- Chip Evacuation: Gravity clears chips efficiently.

- Rigidity: Cast iron construction handles 1,500 N·m cutting torque.

- Tool Capacity: 40+ tool magazines for complex jobs.

- High MRR: Removes 500 cm³/min in steel.

Applications

- Automotive: Engine blocks, transmission cases.

- Railways: Bogie frames, coupling systems.

- Mold Making: Large injection molds.

Operation Steps

- Workholding: Bolt workpiece to angle plate or fixture.

- Tool Setup: Install face mills, shell mills, or indexable cutters.

- Milling Operations:

- Roughing: 5 mm depth of cut at 800 mm/min.

- Finishing: 0.5 mm depth at 2,000 mm/min.

- Coolant Management: High-pressure flood cooling (70 bar).