China Suppliers - Manufacturing Processing Machinery Industry Blog Articles List

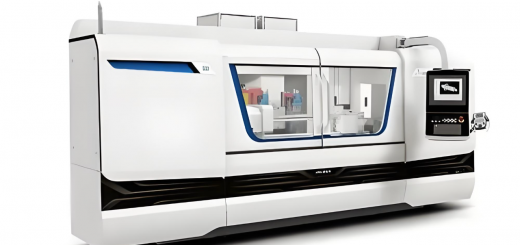

What is a Studer Grinding Machine? A Studer Grinding Machine is a high-precision CNC grinding system designed for cylindrical, surface, and universal grinding applications. Manufactured by Fritz Studer AG (Switzerland), these machines are renowned for sub-micron accuracy (±0.0001...

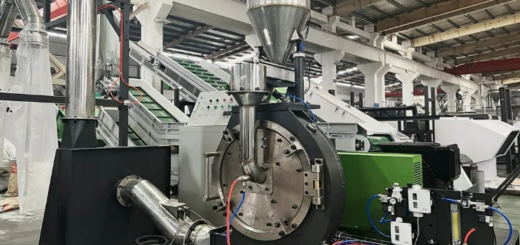

What is a Heavy Duty Grinding Machine? A Heavy Duty Grinding Machine is built for high-material-removal grinding of large parts like turbine shafts, rolls, and press dies. These machines handle workpieces up to 30 tons with rigid frames...

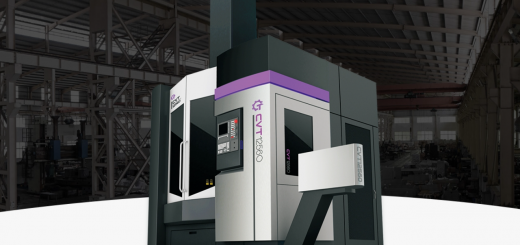

What is a Cutter Grinding Machine? A Cutter Grinding Machine is engineered to produce and refurbish custom cutting tools, including gear hobs, broaches, and custom-profile inserts. It enables precise replication of tool geometries for specialized machining...

What is a Tool Grinding Machine? A Tool Grinding Machine is a specialized CNC or manual machine designed to sharpen, reshape, and maintain cutting tools such as drills, end mills, reamers, and inserts. It ensures optimal...

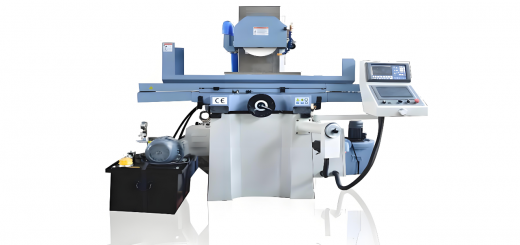

What is an Industrial Grinding Machine? An industrial grinding machine uses abrasive wheels to achieve sub-micron surface finishes (Ra ≤ 0.1μm) and geometric tolerances (±0.001mm) on hardened metals, ceramics, and composites. Types & Specifications Key Advantages Applications Operation Workflow

What is an Automatic Lathe? An automatic lathe produces turned parts with minimal human intervention using cam-driven or CNC-controlled systems. Designed for high-volume output, it excels at manufacturing pins, bushings, and fasteners 24/7. Categories & Mechanisms Type Control Method Output...

What is a Lathe Machining Center? A Lathe Machining Center (LMC) combines CNC turning and milling operations in a single platform, enabling complete machining of complex parts without reclamping. These systems feature live tooling, C/Y-axes, and sub-spindles to perform drilling,...

What is a Vertical Lathe? A vertical lathe (vertical turning center/VTC) clamps workpieces vertically on a rotating table, enabling stable machining of oversized, unbalanced parts (up to 25-ton rings, gears, or molds) impossible for horizontal lathes. Types of Vertical...

What is a Multi-Axis Lathe? A multi-axis lathe combines turning, milling, drilling, and tapping in a single setup using 4–9 computer-controlled axes. It eliminates secondary operations for asymmetric parts like impellers or prosthetics. Categories & Configurations Type...

What is a CNC Grinding Machine? A CNC grinding machine uses computer-controlled abrasive wheels to achieve micron-level precision in surface finishing, dimensional accuracy, and geometry correction for metals, ceramics, and composites. It transforms rough-machined parts into...