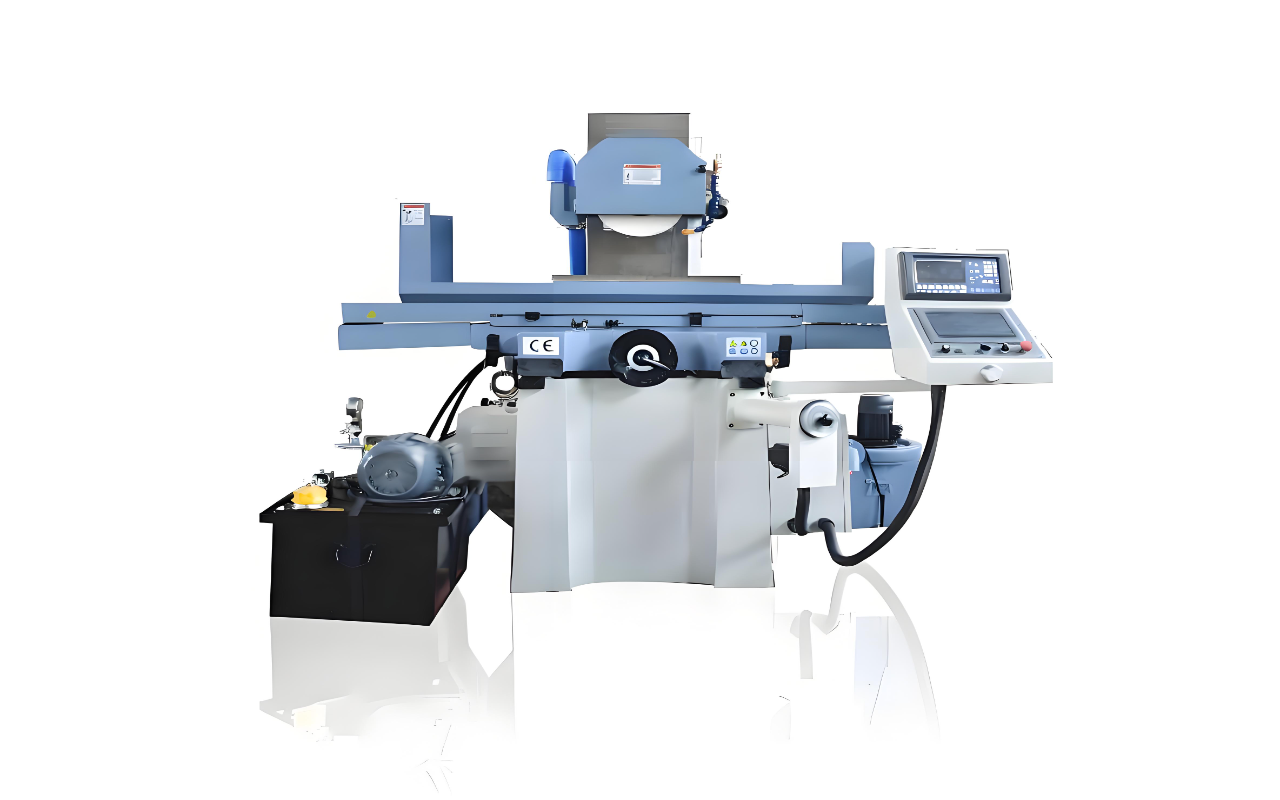

CNC Grinding Machine: Ultra-Precision Surface Finishing for High-Tolerance Components

What is a CNC Grinding Machine?

A CNC grinding machine uses computer-controlled abrasive wheels to achieve micron-level precision in surface finishing, dimensional accuracy, and geometry correction for metals, ceramics, and composites. It transforms rough-machined parts into finished components with tolerances up to ±0.001mm.

Types of CNC Grinding Machines

- Surface Grinders

- For flat surfaces (e.g., mold bases, machine ways).

- Cylindrical Grinders

- External/internal grinding of shafts, bearings.

- Tool & Cutter Grinders

- Resharpens drills, end mills, and inserts.

- Creep-Feed Grinders

- Deep-cut grinding for aerospace turbine blades.

Key Advantages

- Sub-Micron Accuracy: Achieves Ra 0.1μm surface finishes.

- Material Versatility: Handles hardened steel (65 HRC+), carbides, and ceramics.

- Automated Precision: Compensates for thermal drift and wheel wear in real time.

- Cost Efficiency: Reduces manual polishing labor by 90%.

Applications

- Aerospace: Jet engine turbine discs, landing gear.

- Medical: Implant surfaces, surgical tools.

- Automotive: Fuel injection nozzles, transmission gears.

Operation Process

- Workholding: Secure parts with magnetic chucks or vacuum fixtures.

- Wheel Selection: Choose abrasives (diamond, CBN) based on material.

- CNC Programming: Set grinding paths, depth (0.005–0.5mm/pass), and coolant flow.

- In-Process Gauging: Probes measure dimensions mid-operation.

- Finishing: Superfinishing wheels achieve mirror-like surfaces.